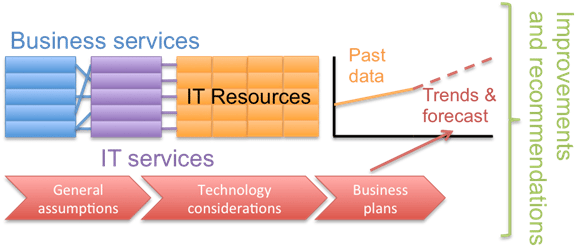

See the answer Subway shops are an example of A level capacity plan A pull strategy Vertical integration A fixedposition layout Low visibilityChecklist Capacity Plan Definition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targets Capacity Planning It's pprove/cancel projects

Ppt Chapter 7 Capacity Planning And Management Powerpoint Presentation Id

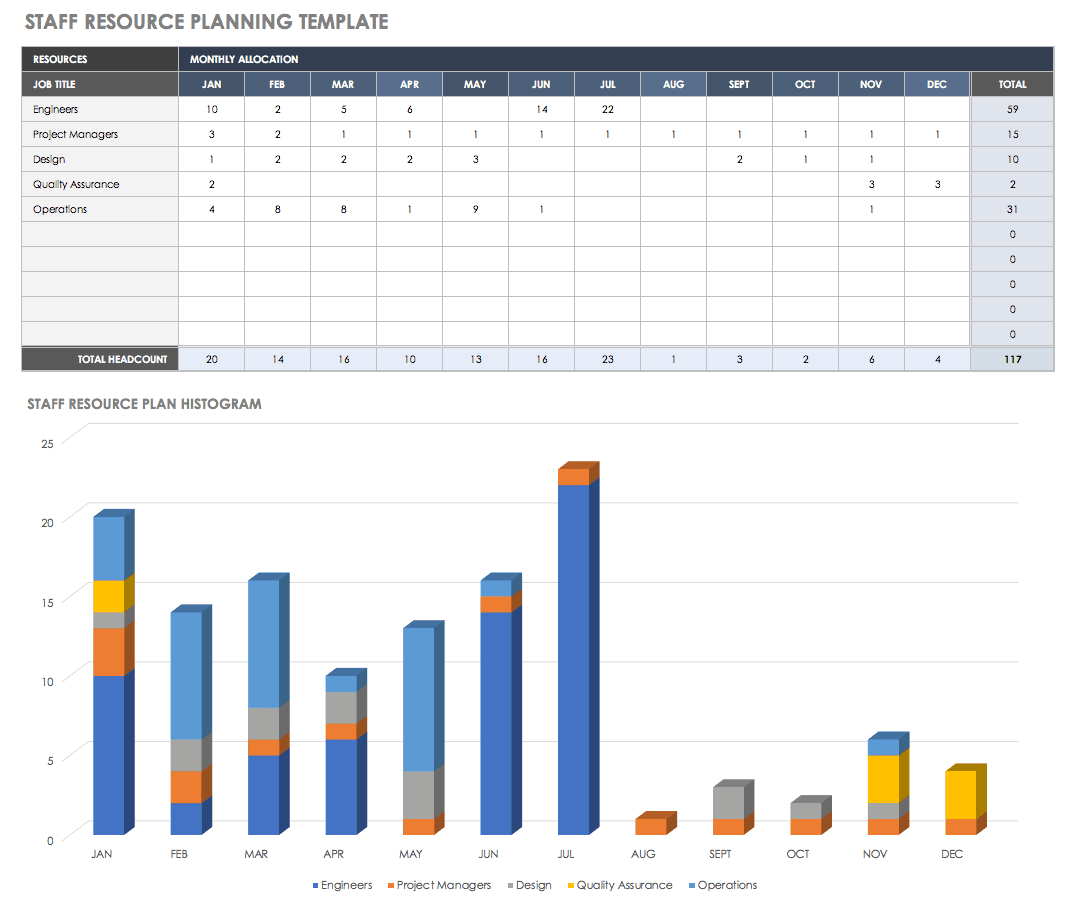

Level capacity plan example

Level capacity plan example-State In 05, for example, 26 facilities spent more than half of the year at or above 95% occupancy of staffed beds Other facilities experienced very high occupancy much less Hospital Capacity, Patient Flow, and Emergency Department Use in New Jersey xi problems in achieving this level of coordination Some of the more crucial areas ofEscalation plan This Plan is a refresh of the Plan developed for 12/13 and builds in learning from that period This plan details the arrangements and procedures that health and social care partners in the C&GH UCPG will utilise in the event of surge and capacity issues, irrespective of cause, affecting one or more partner in order to sustain

Master Production Schedule Wikipedia

Figuring out the ideal time to start production can be a headache when managing your shop floor But you can cure those aches by adopting capacity planning into your business, a model that's going to help you determine the most realistic approach to manufacturing In this article, we look into what is resource capacity planning, how it works, and how you can get What is a level capacity plan?An example of this is when a firm has employees that work for like hours a week, then the firm has 400 weekly working capacity Without putting overtime in the equation, it means the firm can take care of a maximum of 400 hours in a week

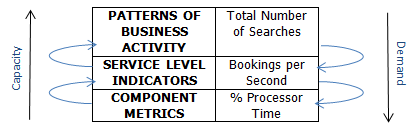

Purpose of Capacity Plan Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands Example of Capacity Management procedure Capacity Management is the continuous and iterative process that monitors, analyses, and evaluates the performance and capacity of the IT infrastructure and, with the data obtained, it optimizes the service or submits an RFC to Change Management All the information obtained in these activities, andThis method is a farcry from having an accurate substitute to replace Erlang for interval level forecasting, but it will get the job done for high level capacity planning As mentioned at the start of this article this is the first part of a two part series on capacity planning

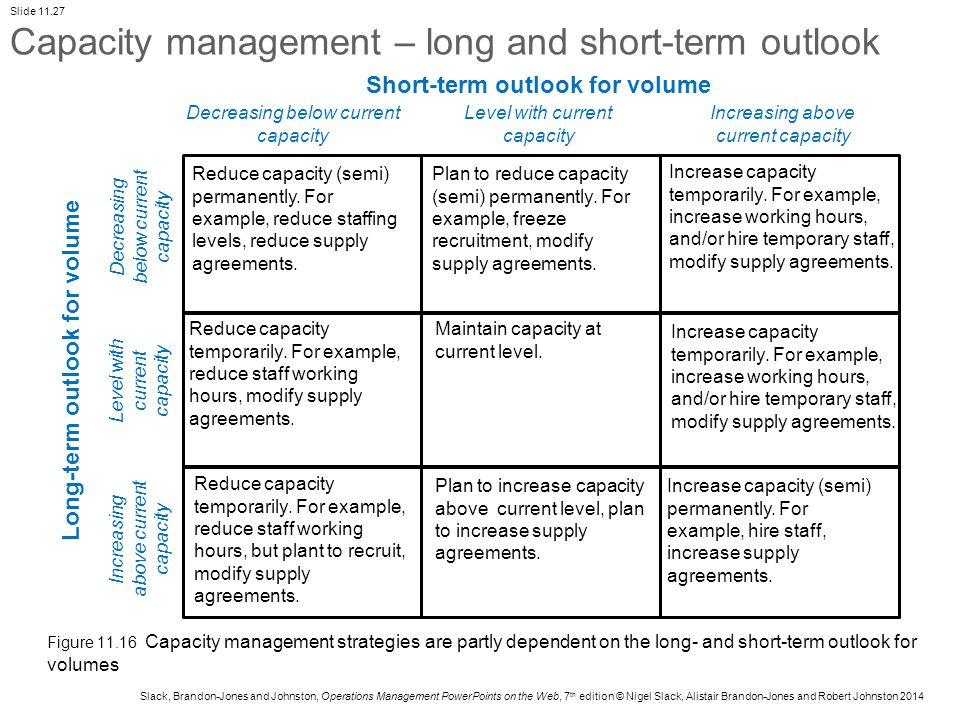

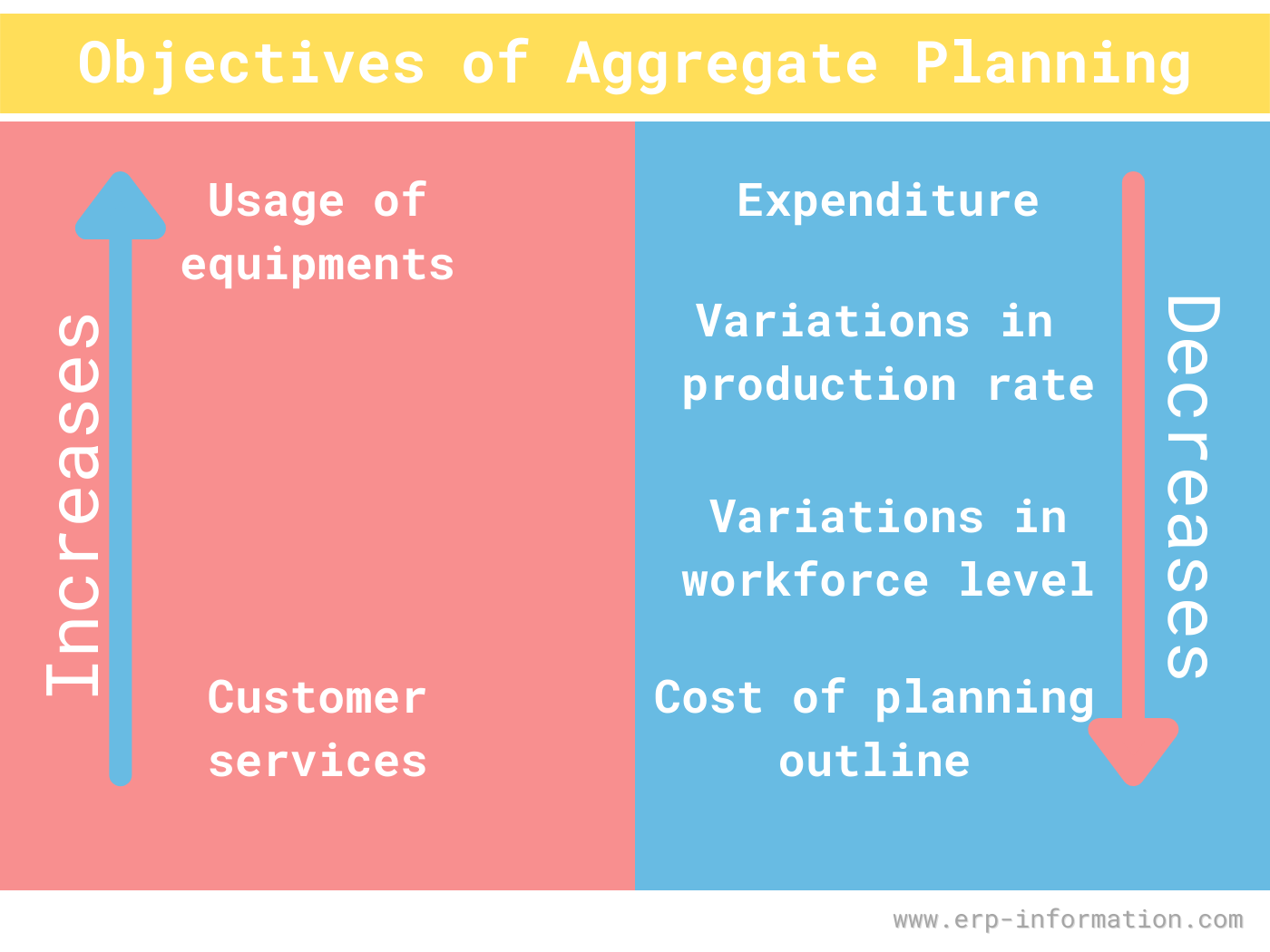

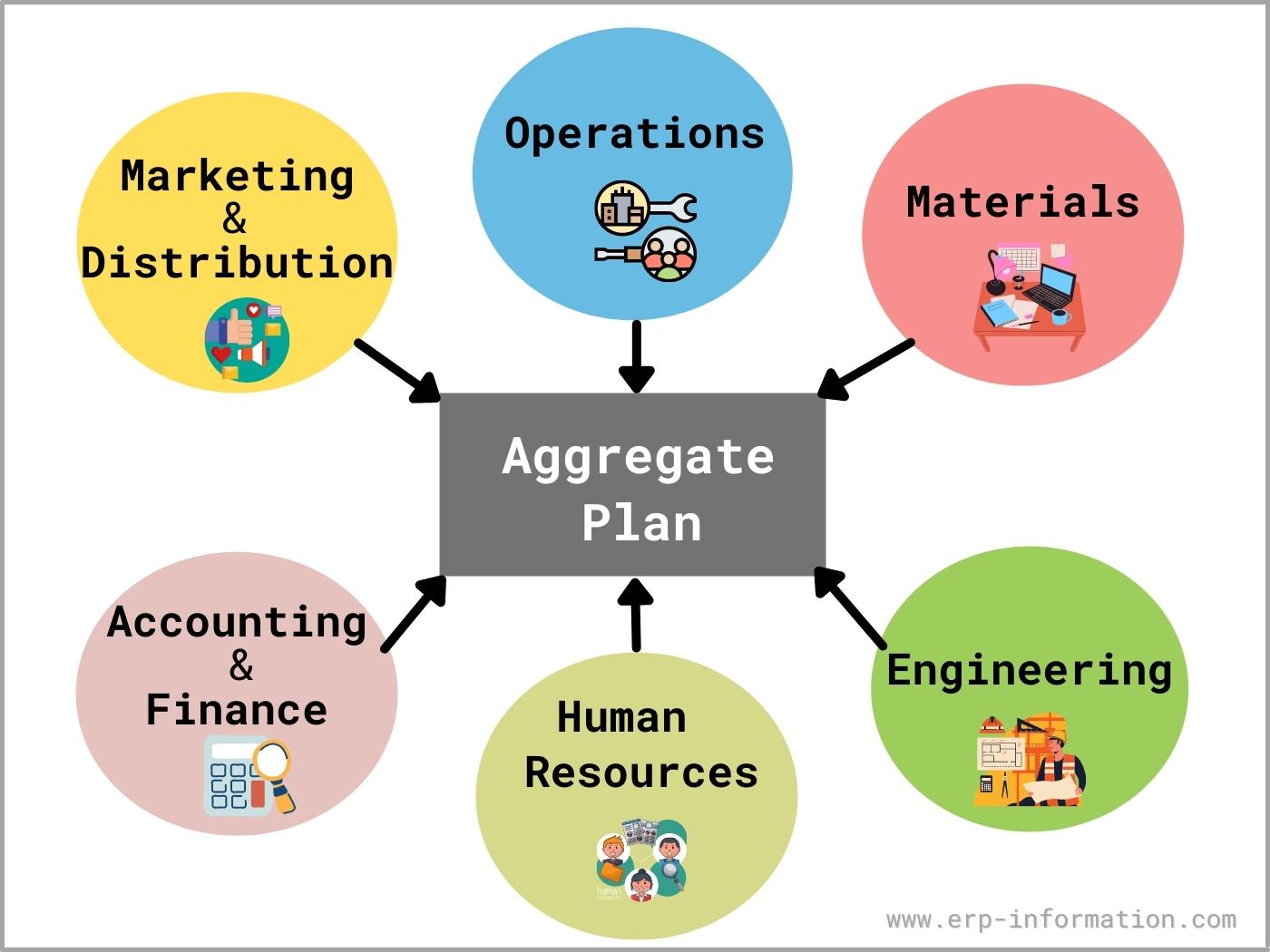

And the capacity level for each period that maximizes the firm's (supply chain's) profit over the planning horizon – Specify the planning horizon (typically 3 to 18 months) – Specify the duration of each period (typically 1 month for longer horizons) – Specify key information required to develop an aggregate plan The Conference of the Parties adopted the Action Plan on Capacitybuilding for access and benefitsharing at its seventh meeting, in February 04 (decision VII/19F)The COP invited Parties and Governments and relevant organizations to use the Action Plan when designing and implementing national, regional and subregional plans and strategies to build capacities for 148 122 40% x 393 142=300 Surge Capacity 180 142 or 79% Plan for 300 Capacity Kaiser 2/23/06 Critical care/monitored beds 70 60 General medical – surgical beds (Unmonitored) 96 37% x 393 148 =296 Surge Capacity 166 148 or % Plan for 296 Capacity TOTAL 452 355

Capacity Utilization Definition Example And Economic Significance

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

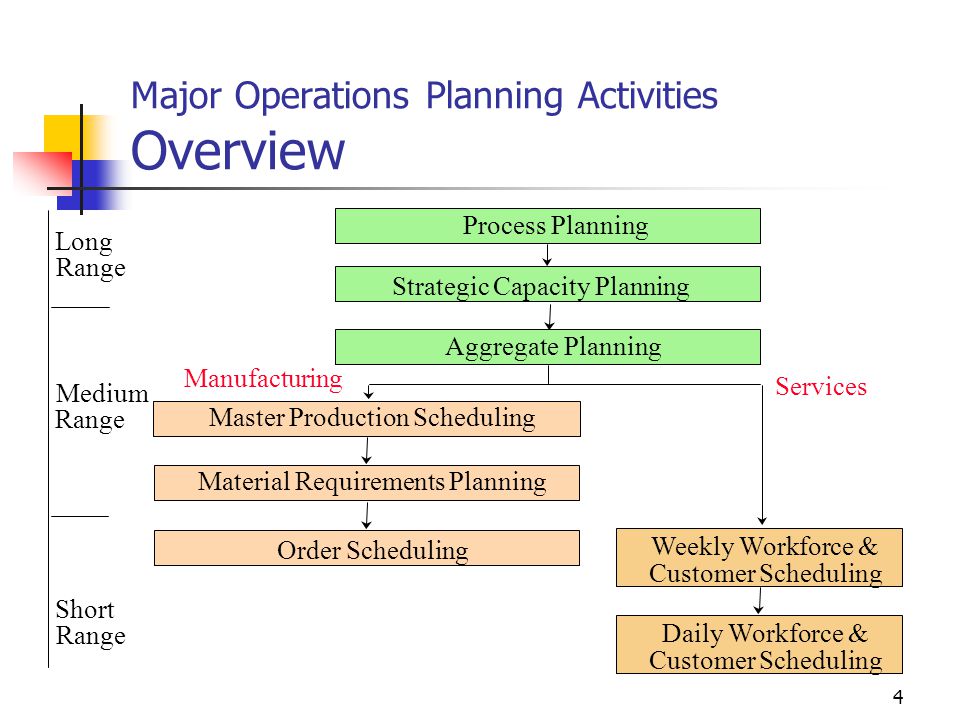

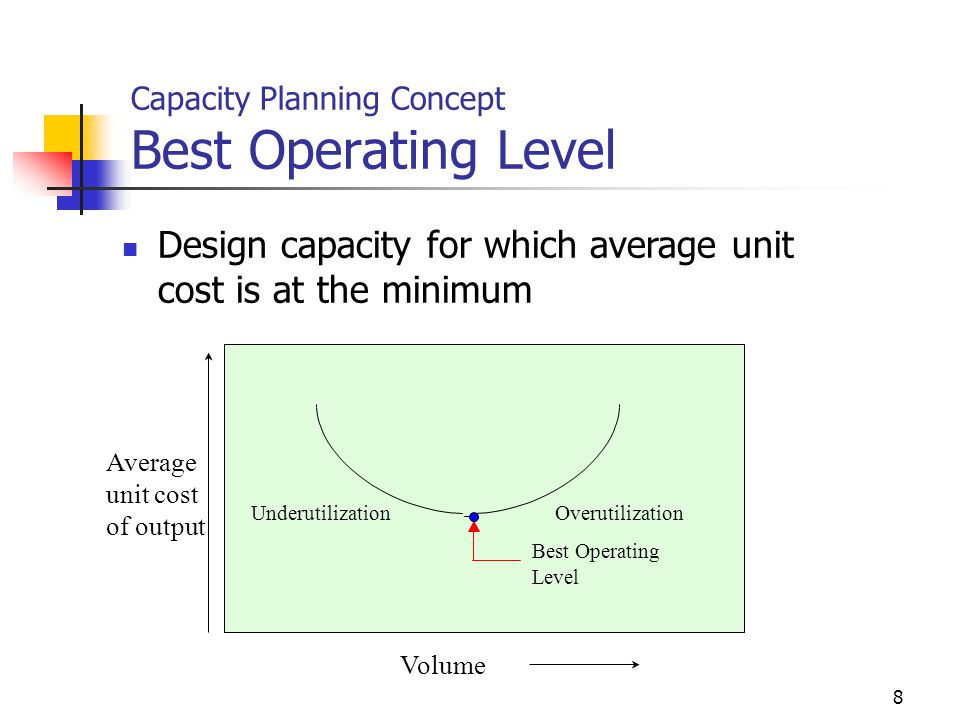

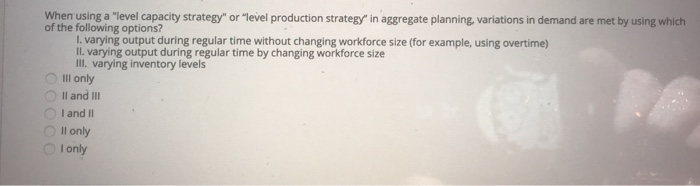

Use break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skills1 Capacity Development Working Group (WG) Terms of Reference (June 10) 2 Organizational Capacity Assessment Sheet (version 2) 3 Individual Capacity Assessment Sheet (version 1 and version 2) 4 Sample of Programme Design Matrix (PDM) 5 Sample of Plan of Operation (PO) 6 Evaluation Sheet for final PresentationThe level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to follow

Capacity Plan Template Ms Office Templates Forms Checklists For Ms Office And Apple Iwork

23 Best Capacity Planning Ideas Capacity Planning Capacity How To Plan

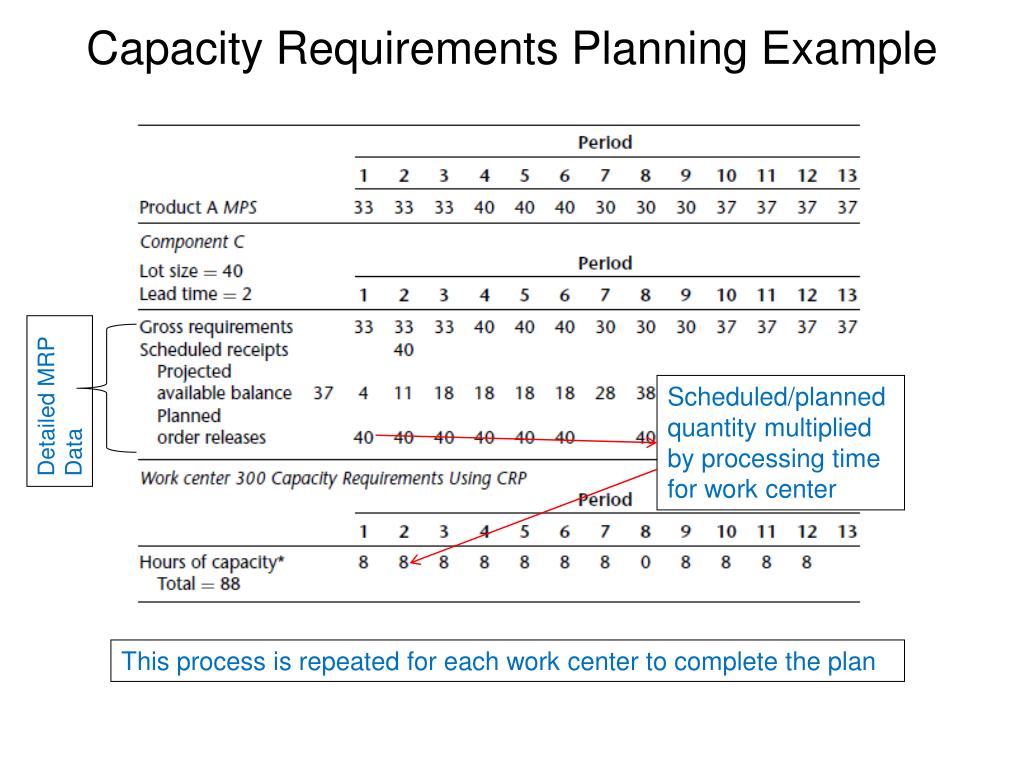

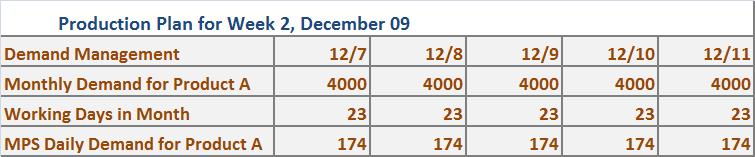

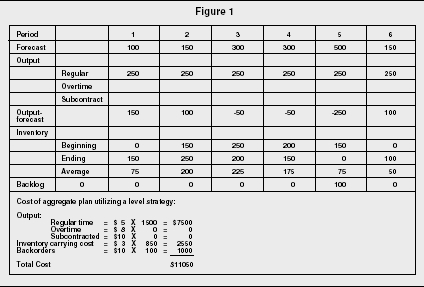

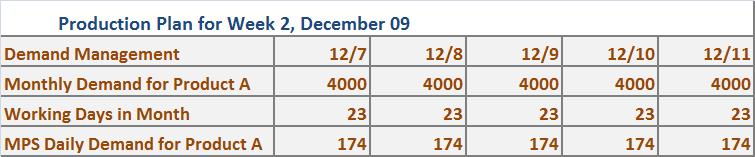

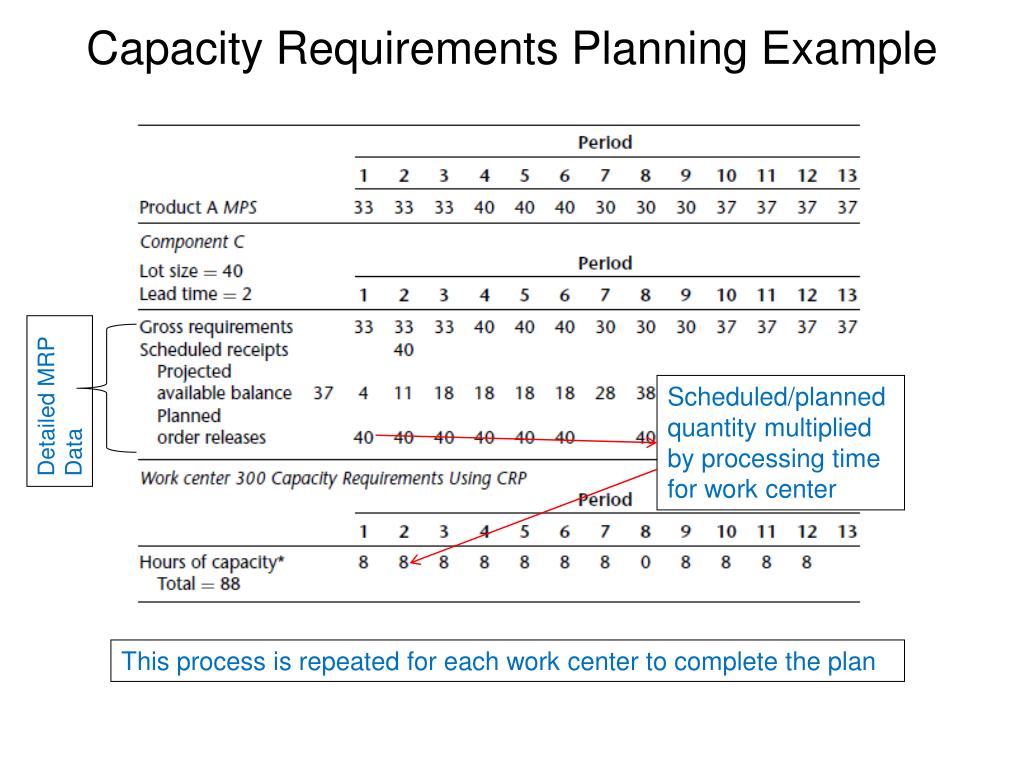

An example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina) Step 1 Gathering Project Information Gather a list of projects which are to be planned for the specified duration Collect highlevel estimates for the projects During the capacity planning phase, it is natural to not have detailed estimates and WBSProduction, Capacity and Material Planning a Production plan `quantities of final product, subassemblies, parts needed at distinct points in time a To generate the Production plan we need `endproduct demand forecasts `Master production schedule a Master production schedule (MPS) `delivery plan for the manufacturing organization

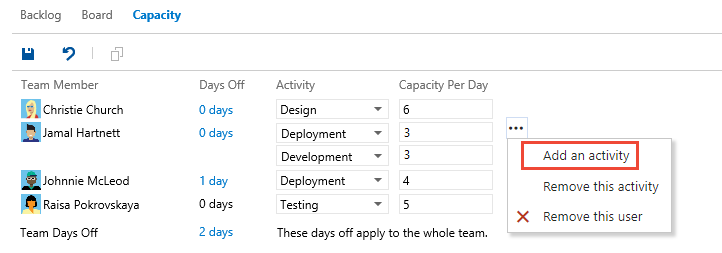

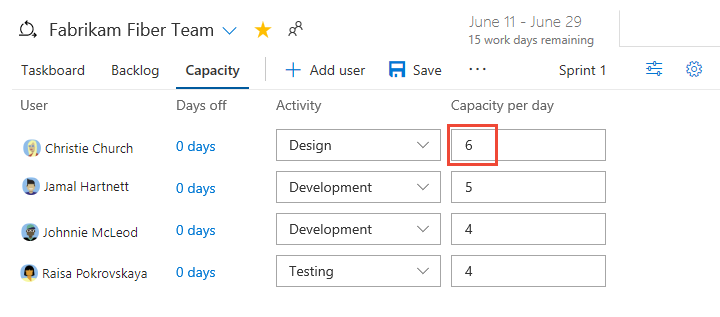

Set Sprint Capacity Azure Boards Microsoft Docs

Workclout 3 Case Studies Examples Of Capacity Planning

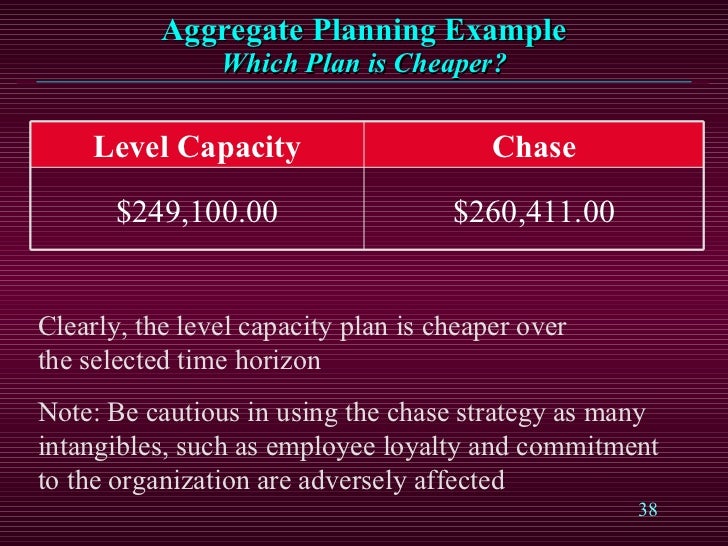

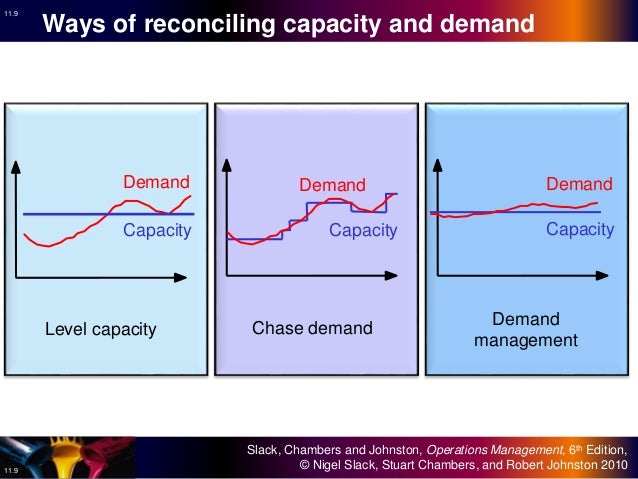

2 days ago An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storage10 Annual Sales Plan Examples; Capacity, Route Planning, and Scheduling An Efficient Trifecta Once you've got your highlevel (capacity) plan in place, you can use it as a guide for scheduling and route planning You'll want to use all three together to achieve the highest level of logistical efficiency We are here to help with all three

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

Capacity Matching Productive Resource To Demand Ppt Download

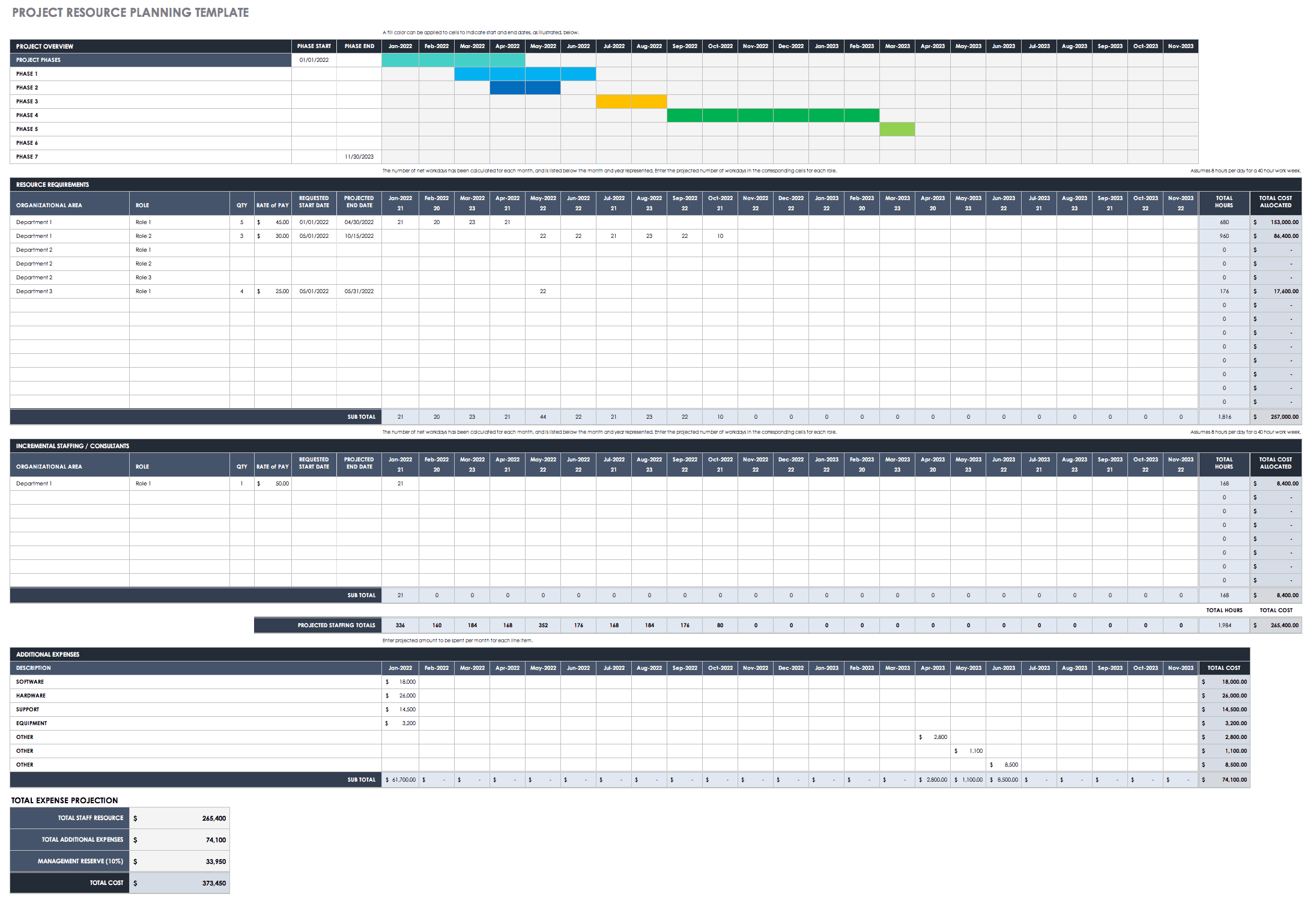

Further, the key outcome of using a production capacity template excel spreadsheet is to keep the product inventory to a minimum level even fulfilling the customer demands So, good capacity planning for production results in a positive response to the fluctuation in product demand in different seasons over the product lifecycleThis problem has been solved! 3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacity

Resource And Capacity Management

1

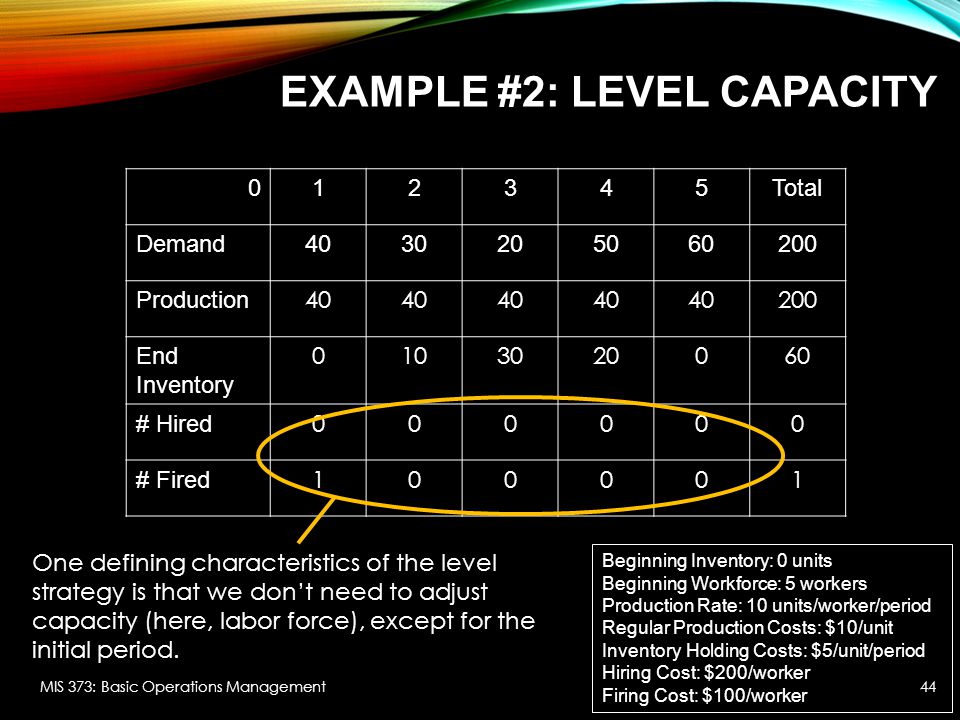

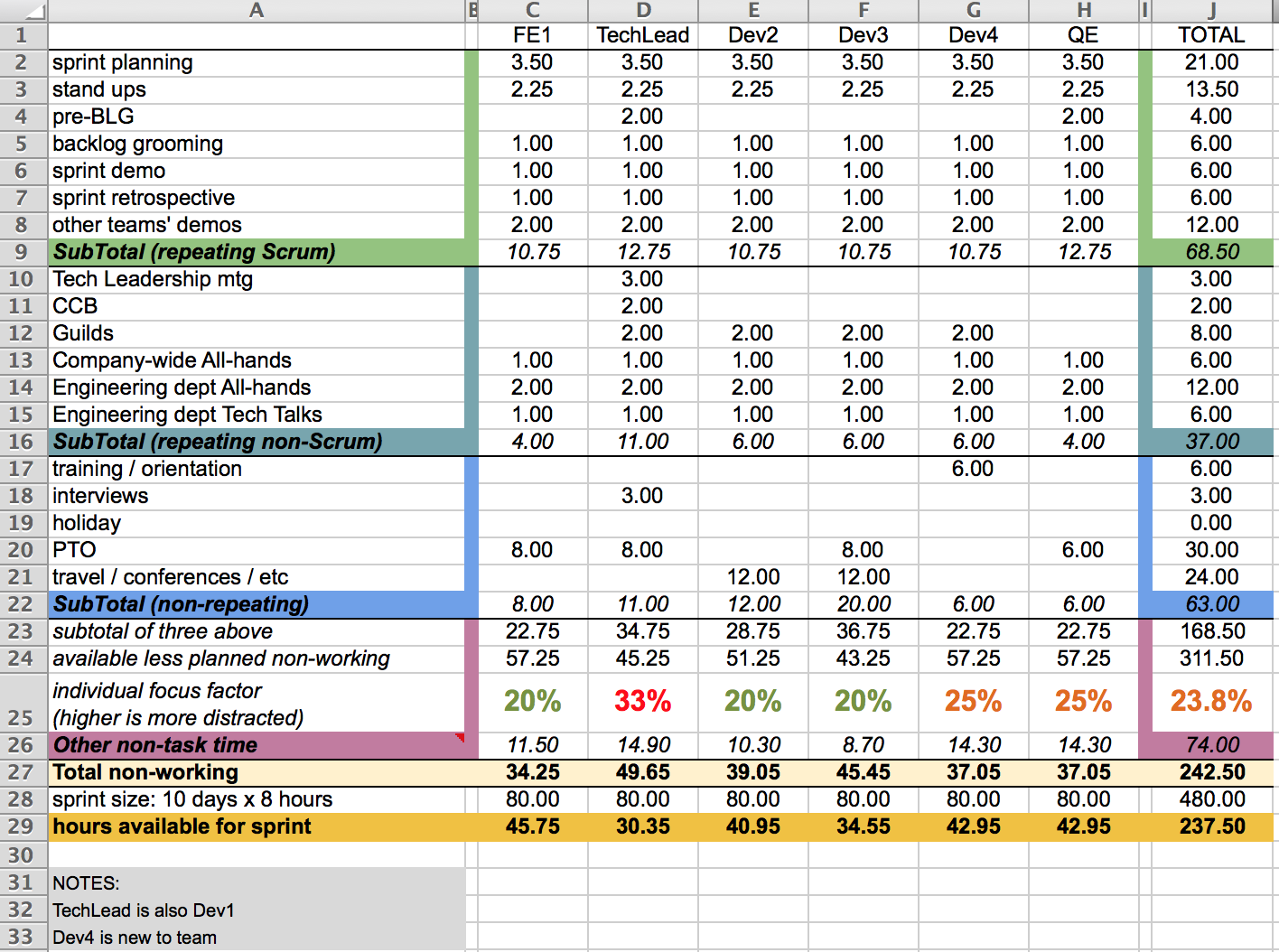

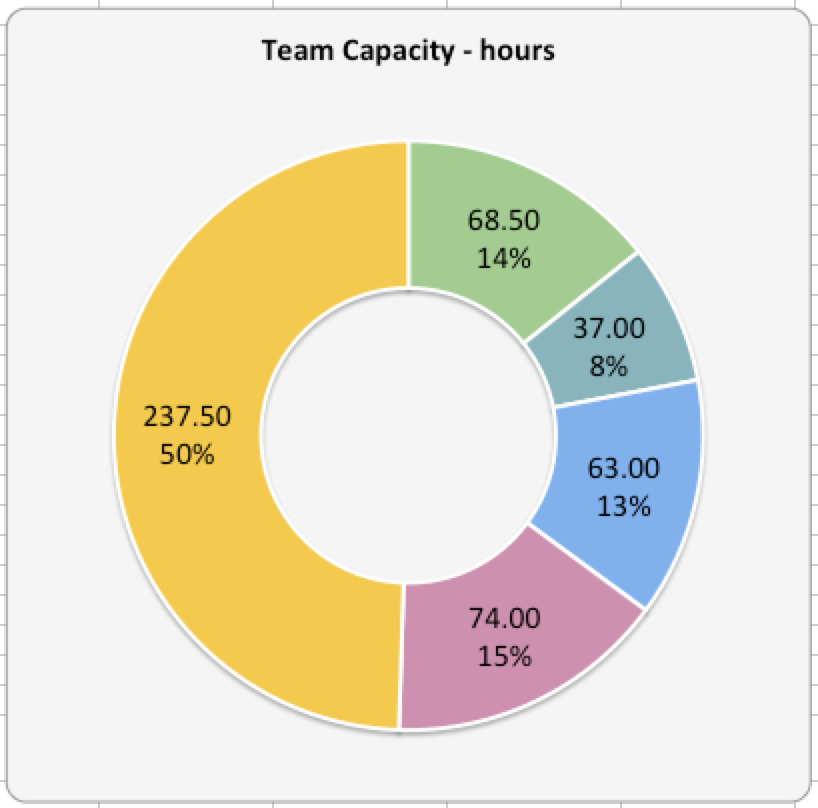

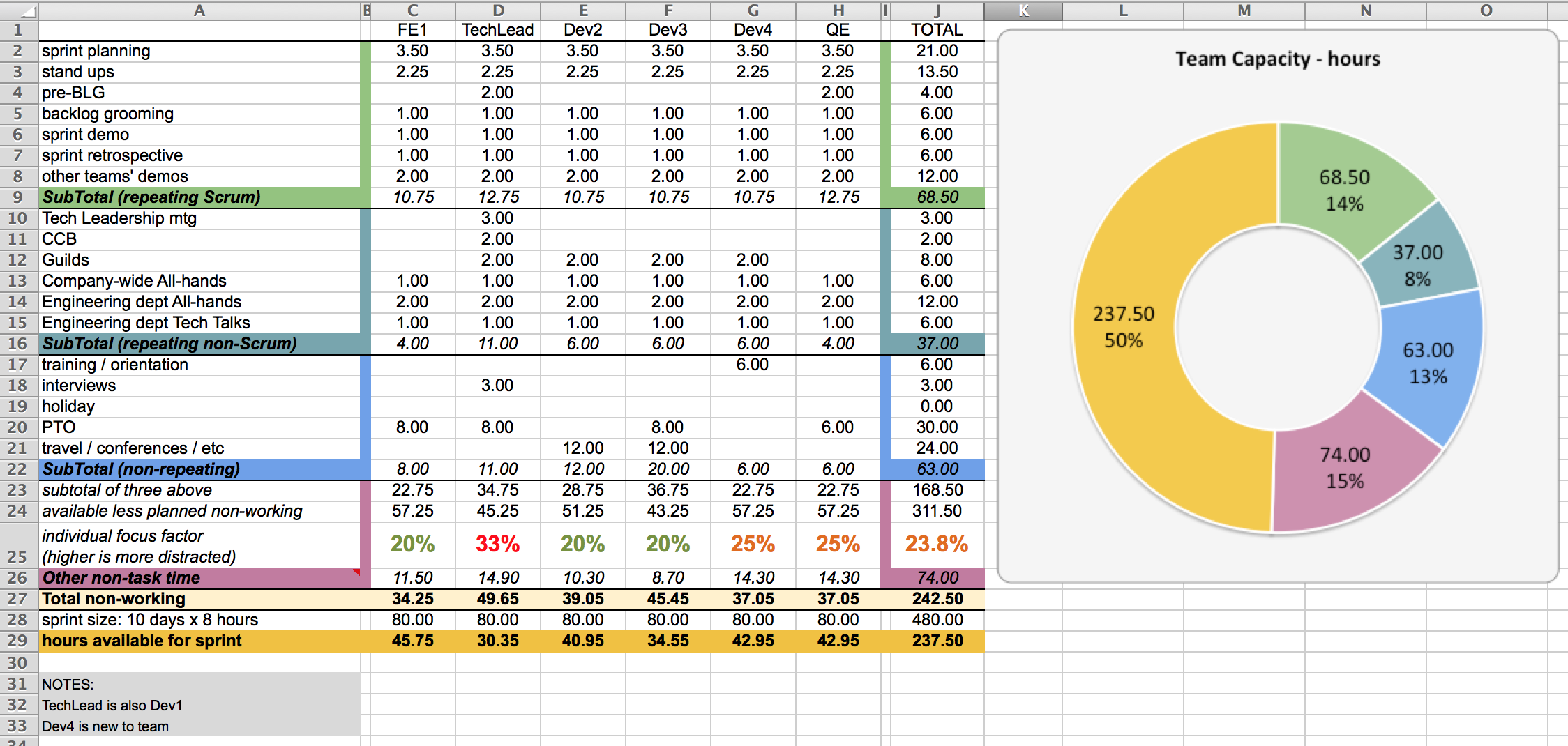

A period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demandResource level Capacity vs Demand Clearly two resources Developer 3 and Developer 2 do not have enough capacity to complete the tasks assigned to them Meanwhile, 3 other resources have a lot of additional hours available but not utilized In the next page of the dashboard, you can see the charts of Capacity vs Demand in Hours Here is a very basic example of what a high level capacity plan looks like Model Tips Create excel tables that allow flexibility and automation For example, set up a formula so when any of the influencers change up or down, the capacity plan updates on its own (This allows you to leverage "what if" scenarios)

Chapter 3 Strategic Capacity Management Ppt Video Online Download

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

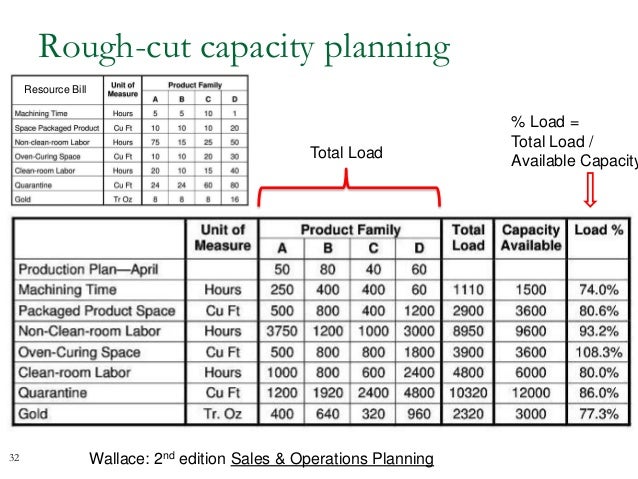

19 Project Action Plan Examples;This revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high u 32 Example RoughCut Capacity Planning Texprint Company makes a line of computer printers on a producetostock basis for other computer manufacturers Each printer requires an average of 24 laborhours The plant uses a backlog of orders to allow a levelcapacity aggregate plan This plan provides a weekly capacity of 5,000 labor hours

What Is Capacity Planning Examples Types Optimoroute

Capacity Planning Meaning Classification And Its Goals

Level Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers ( working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventorySample Capacity Building Plan DRAFT Rev 10 4 Guiding Principles During the Change It is important for Organization ABC personnel to follow these principles as it implements the actions in this Plan 1 Focus on what is needed to change, not on the way it has always been done before 2UPMC St Margaret Hospital Surge Response Plan 1 LEVEL DEFINITION AND CRITERIA NEDOCS Score and Interpretation LEVEL 1 – 2 NEDOCS = 0 – 60 Not busy busy LEVEL 3 NEDOCS = 61 – 100 Extremely Busy, not overcrowded LEVEL 4 NEDOCS = 101 140 Overcrowded LEVEL 5 NEDOCS = 141 – 180 Extremely Overcrowded Level 6 NEDOCS = 181 – 0

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

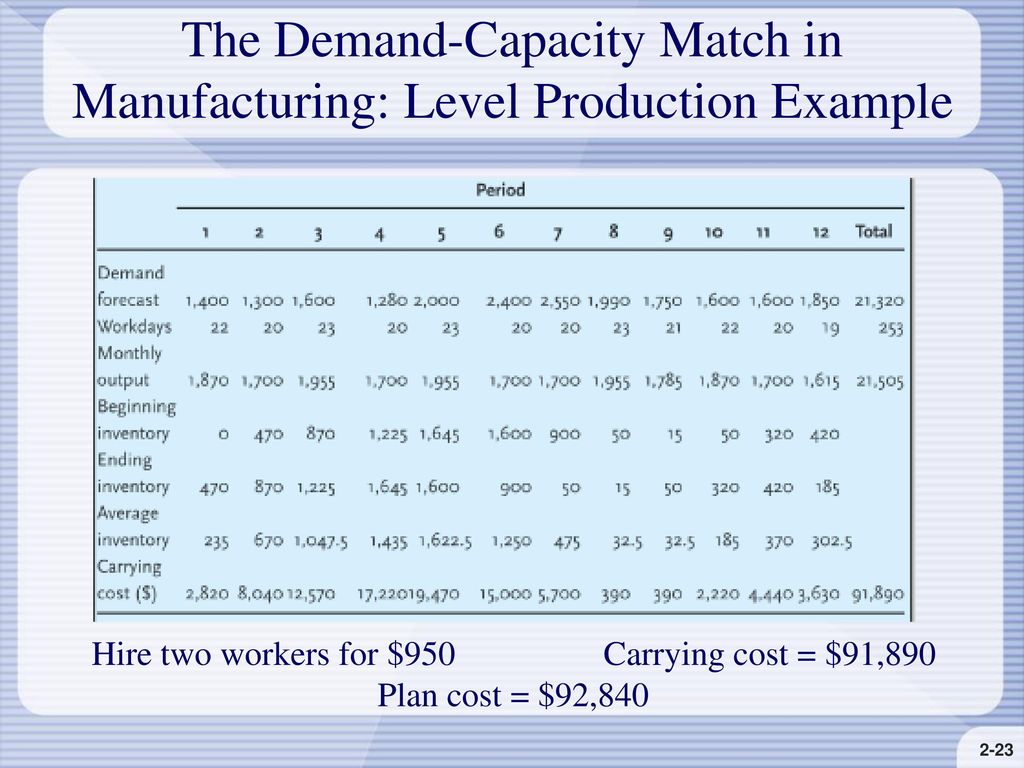

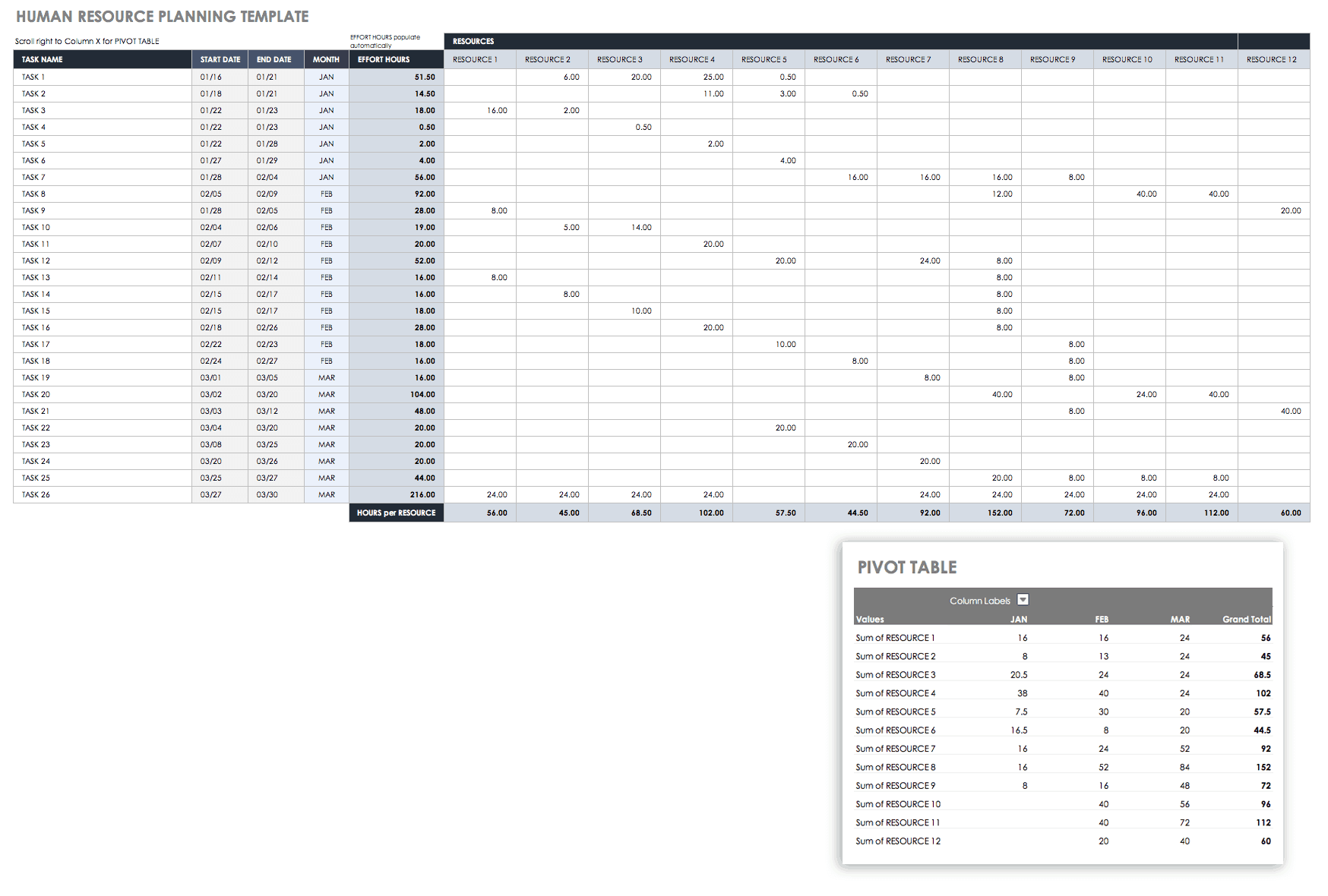

Level Production Strategy We are going to find the requirements for the entire period of the plan and also produce the average amount that is needed per month in order to meet the plan First we are going to determine the total average requirements per month Avg requirements = total number of requirements – opening inv closing invYou would often need different tools for detailed project plans and highlevel planning, as they allow you to focus either on managing particular tasks or managing and assigning resources throughout the projectsStep by step demo on how to plan resource capacity using Excel template Tutorial https//indzaracom/resourcecapacityplannerexceltemplatestep

Capacity Planning And Control

Capacity Planning Basics Part 1 Of 2 Wfmanagement

Capacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40The idea here is that a level schedule is used during consistent periods and the chase strategy is used during months with fluctuating demand This can be helpful in seasonal business For example, a company that made Halloween chocolates, may maintain a level schedule for 9 months of the year and then use a chase strategy during the weeksLevel capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about the demand of the product He or she may have to use some strategies to meet this uneven and everchanging demand pattern These include pure strategies and strategy which uses a

Capacity Plan Template Word Templates For Free Download

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

Have a plan for assisting nonregistered visitors and guests back to the registration area 5 Consider written guidelines to be handed out to the visitors and guests after they register Identify languagespecific and readinglevel appropriate materials for To calculate special machine capacity per month , the available machines are 10 , work hours /day are 8 hours , efficiency level is 80% and working days per month is 26 days Special production capacity in time / month = 10 machines x 480 Mins x 80 / 100 = 3840 Mins / day 3840 Mines x 26 days = Mins / month or 1664 hours /month 2

Chapter 11 Capacity Management Ppt Video Online Download

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

23 Best Capacity Planning Ideas Capacity Planning Capacity How To Plan

What Is Capacity Planning Examples Types Optimoroute

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Excel Based Resource Plan Template Free Download Project Management Templates

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Master Production Schedule Wikipedia

When Using A Level Capacity Strategy Or Level Chegg Com

Set Sprint Capacity Azure Boards Microsoft Docs

Production Planning Wikipedia

Capacity Plan Template Ms Word Templates Forms Checklists For Ms Office And Apple Iwork

Set Sprint Capacity Azure Boards Microsoft Docs

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Roadmap Scaled Agile Framework

Itil Service Design Itil Capacity Plan

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Roadmap Scaled Agile Framework

Short Term Capacity Planning Big Bang

Doc Capacity Planning Training Class Mike Gholi Academia Edu

Capacity Management Process Handbook

Excel Based Resource Plan Template Free Download Project Management Templates

26 Resource Capacity Plan Template Resource Planning Template Human Capacity Project Business Letter Template Action Plan Template Business Plan Template Free

Capacity Planning Worksheet For Scrum Teams Agile Coffee

Capacity Planning Template Atlassian

Building A Supply Plan For The Holiday Season Relex Solutions

Capacity Planning Template Free Download

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

1

How To Calculate Production Capacity Of A Factory

Capacity Planning Example

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

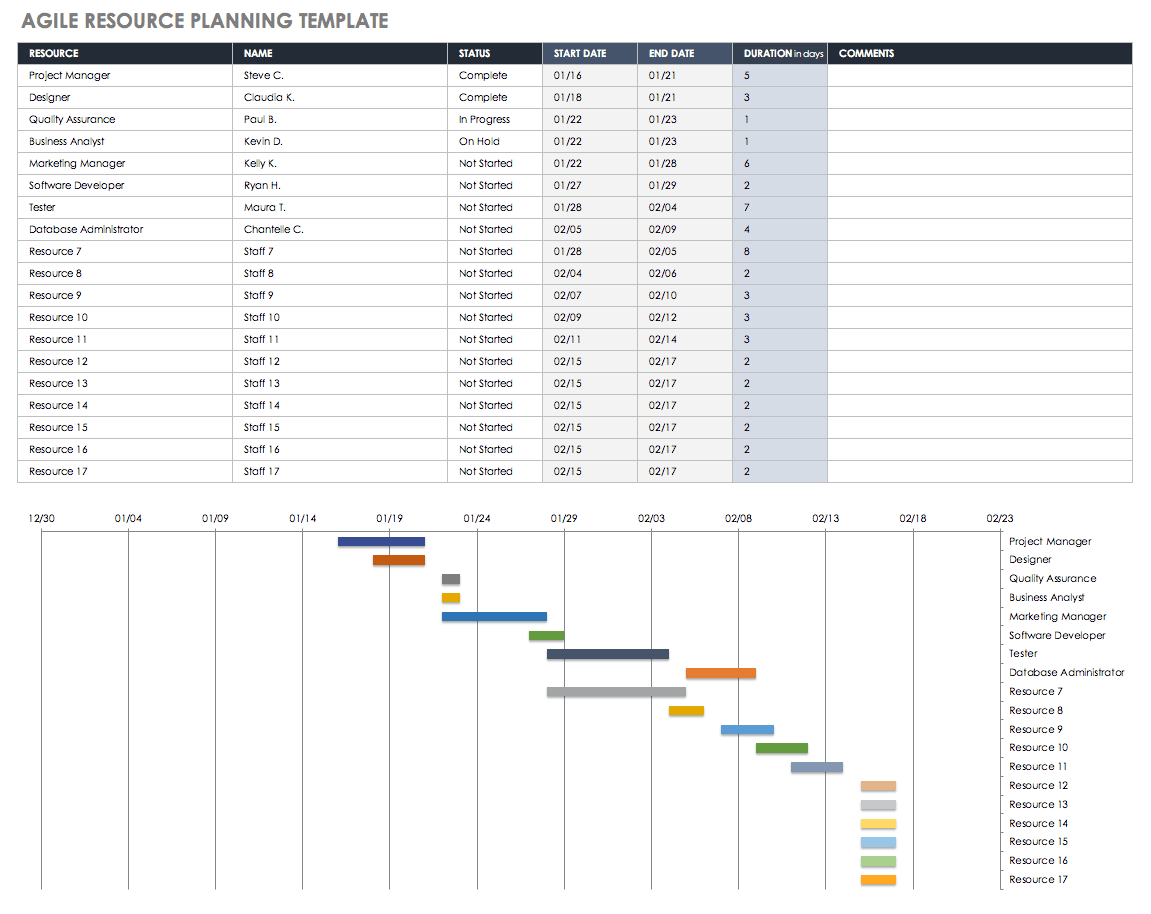

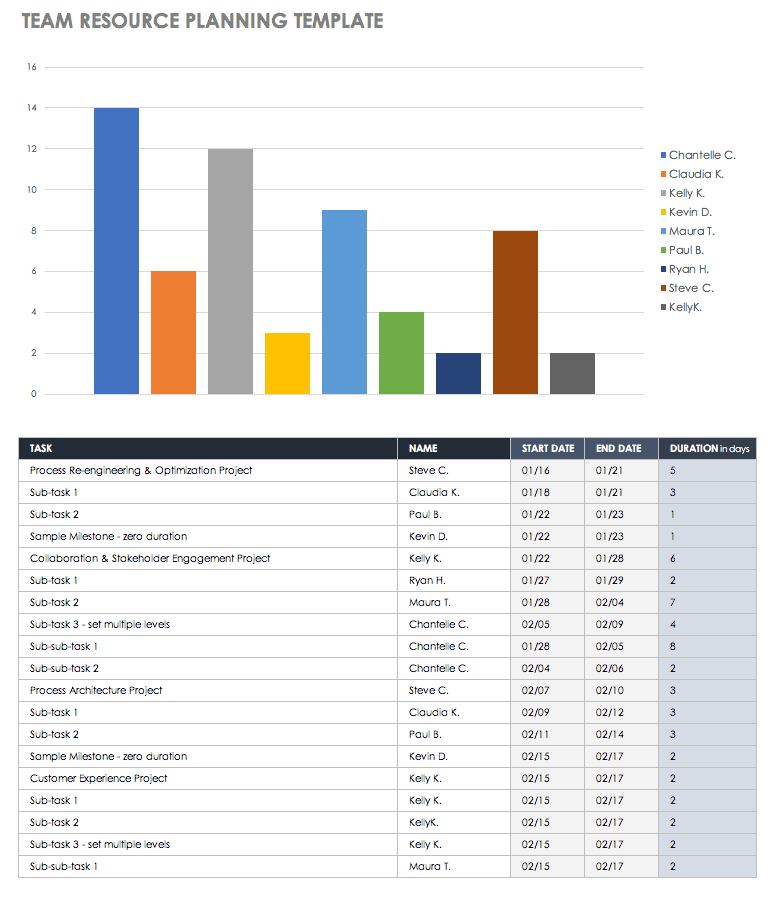

Free Resource Planning Templates Smartsheet

Sales Amp Operations Planning

23 Best Capacity Planning Ideas Capacity Planning Capacity How To Plan

Iteration Planning Scaled Agile Framework

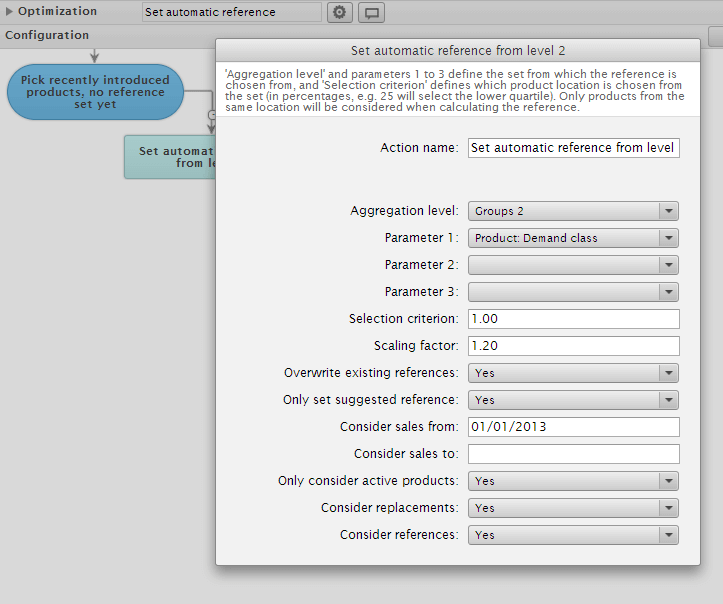

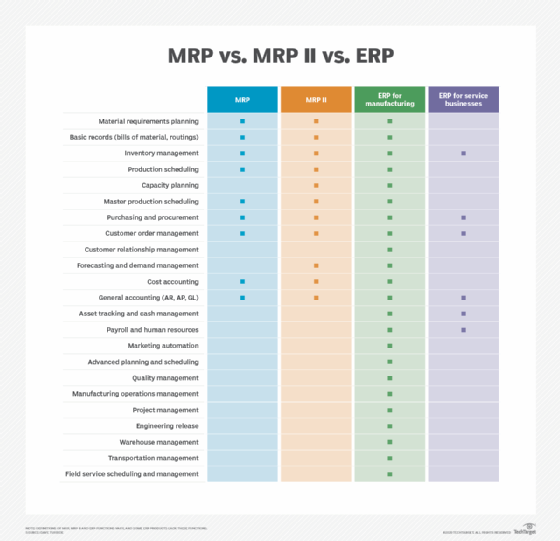

What Is Material Requirements Planning Mrp

Resource And Capacity Management

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Capacity Planning Template Atlassian

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Planning Template Atlassian

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

Free Resource Planning Templates Smartsheet

A Critical Insight To Successful Supply Chain Planning

1

Software For Capacity Planning

Checklist Capacity Plan It Process Wiki

11 Capacity Planning And Control Operations Management

Klauuuudia Itil Capacity Plan Template

Excel Based Resource Plan Template Free Download Project Management Templates

Aggregate Production Planning

Capacity Planning Example

Free Resource Planning Templates Smartsheet

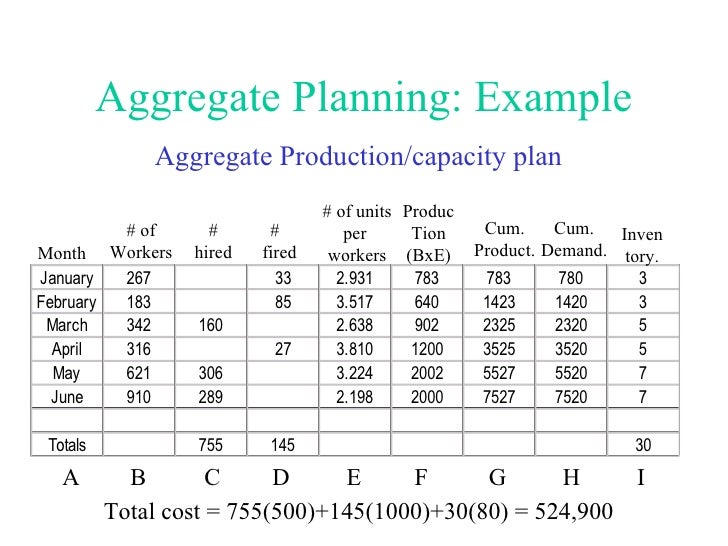

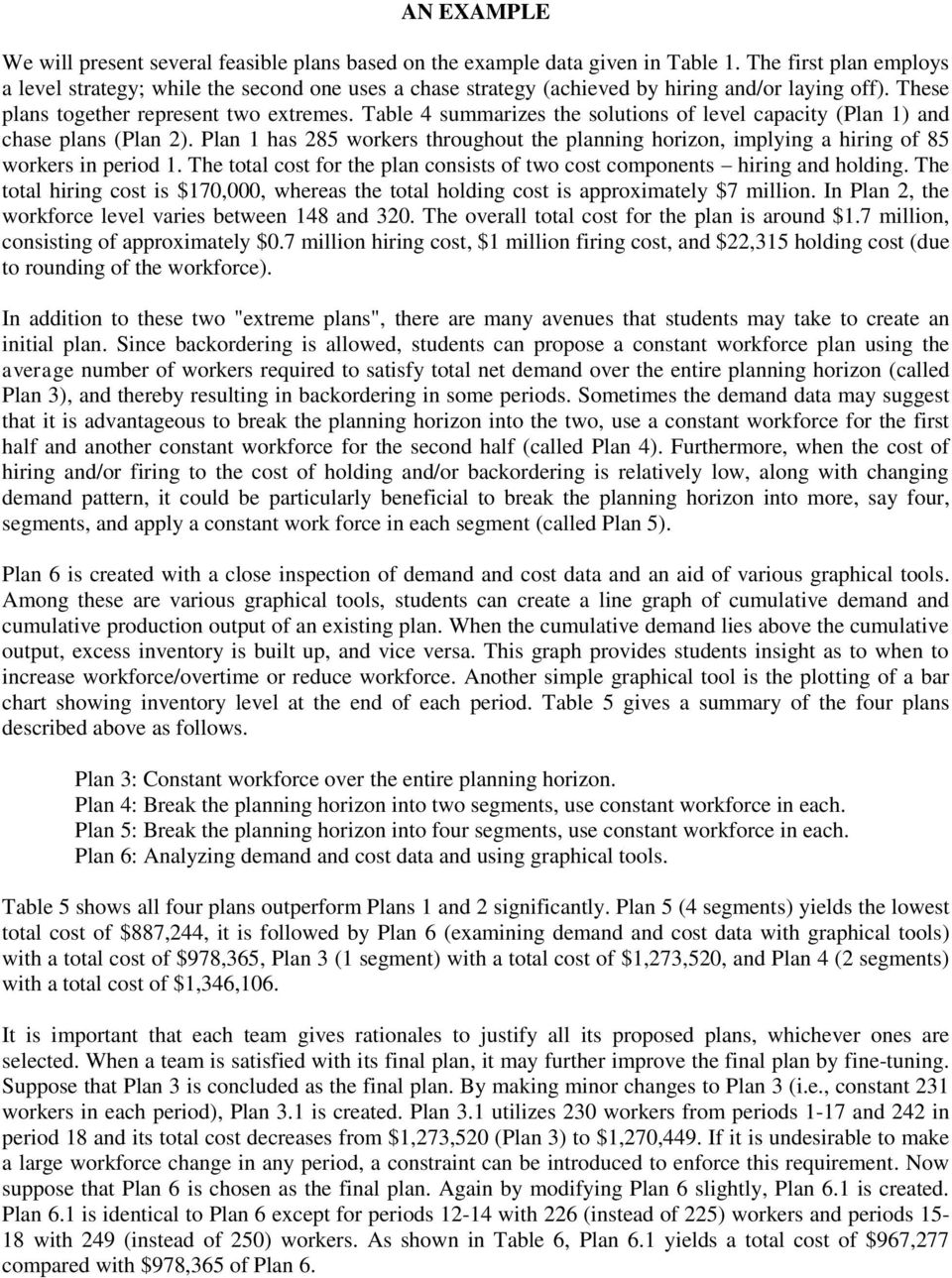

Teaching Aggregate Planning In An Operations Management Course Pdf Free Download

What Is Capacity Planning Examples Types Optimoroute

Capacity Planning Worksheet For Scrum Teams Agile Coffee

1

3 Level Capacity Management Case Study

Capacity Planning And Control Ppt Download

Ppt Chapter 7 Capacity Planning And Management Powerpoint Presentation Id

Capacity Plan Template Word Templates For Free Download

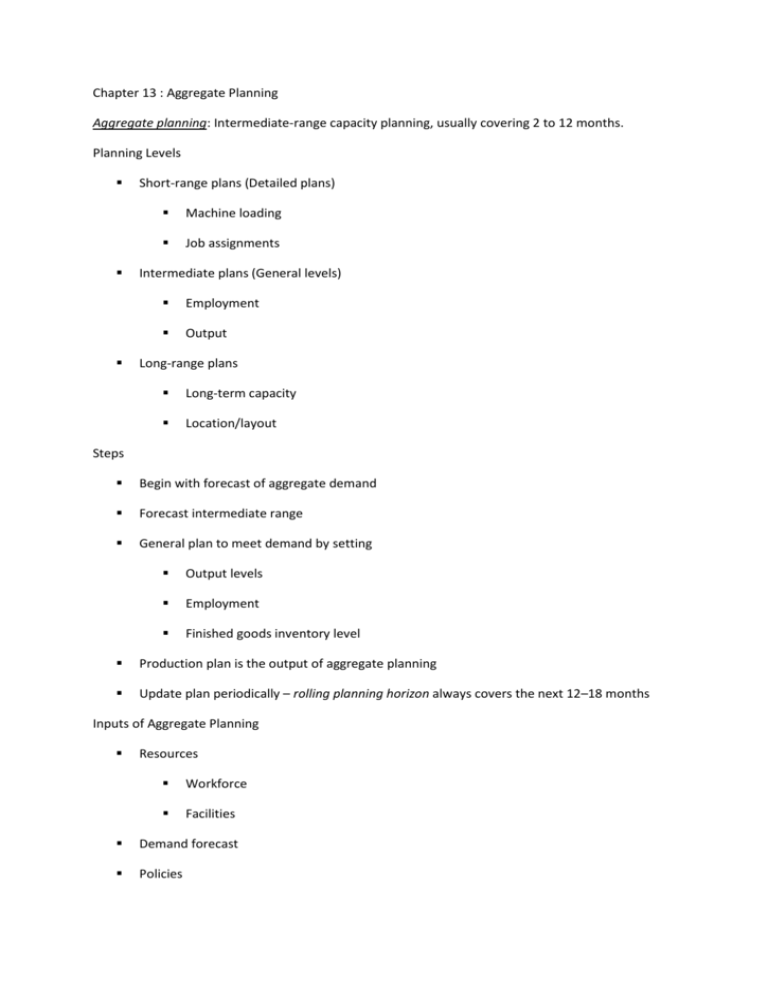

Chapter 13 Aggregate Planning

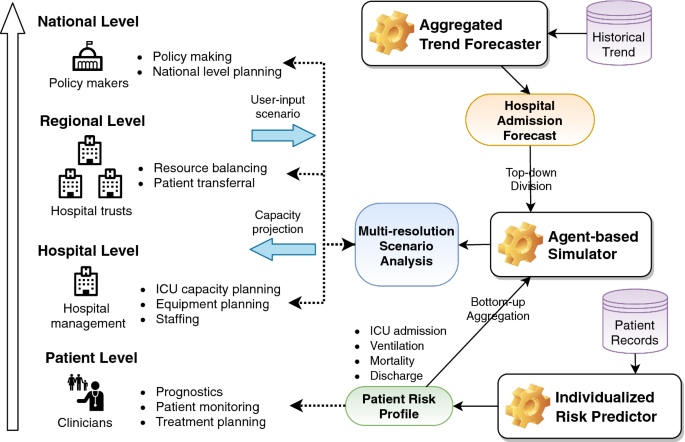

Cpas The Uk S National Machine Learning Based Hospital Capacity Planning System For Covid 19 Springerlink

Entries For Thursday 25 October 07 Sergio S Blog

Capacity Planning Worksheet For Scrum Teams Agile Coffee

7 1 Capacity Planning Saylor Bus300 Operations Management

Set Sprint Capacity Azure Boards Microsoft Docs

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Plan Template Ms Word Templates Forms Checklists For Ms Office And Apple Iwork

Agile Planning Step By Step Guide Template Monday Com Blog

Capacity Planning Under Uncertainty Che 5480 Economic Decision

Uninote Ecommerce S3 Eu West 2 Amazonaws Com Capacity management Pdf

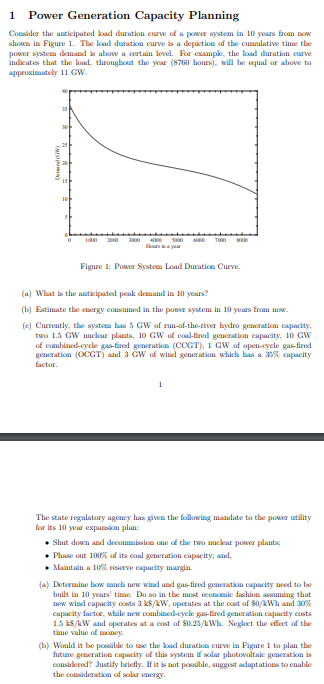

1 Power Generation Capacity Planning Consider The Chegg Com

Capacity Planning Basics Part 1 Of 2 Wfmanagement

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

What Is Capacity Planning Examples Types Optimoroute

What Is Capacity Planning Examples Types Optimoroute

Free Resource Planning Templates Smartsheet

Checklist Capacity Plan It Process Wiki

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

L D Capacity Planning Checklist 5 Steps To Effective Resource Management Synapse

Free Resource Planning Templates Smartsheet

0 件のコメント:

コメントを投稿